A few weeks ago the World Climate Conference was held to discuss sustainability targets for lower energy consumption and less pollution. Few organisations have embraced the goals but Festo, at its Scharnhausen Technology Plant in Germany, has already shown its support for them in the Industry 4.0, energy efficient, IoT-enabled factory

Energy efficiency often starts from the ground up in manufacturing environments and, for Festo, a major decision was to develop an energy efficiency module that is a plug-and-work solution for the pneumatic circuit as a whole. The module is able to summarise, evaluate and analyse data by using artificial intelligence (AI). The data collected can therefore be pre-processed inside the unit and/or completely transferred into a cloud. A decentralised automation platform usually collects data from different Festo devices and combines them on a valve terminal with Codesys controller on board.

In the Festo Technology Plant at Scharnhausen, this type of installation has been retrofitted to all older machines since 2015 – and is a must for all new machines. The target was to make them energy transparent and to optimise air and current consumption by dedicated switching-on and off cycles depending on several criteria – thus avoiding that energy peaks are just added without any benefit, or leakage causing high extra cost. Data had been fed via object linking and embedding (OLE) for process control (OPC) unified architecture (UA) into the on-site manufacturing execution (ME) system from SAP by its plant connection module (PCo), and further to the enterprise resource planning (ERP) system with SAP HANA cloud. Now the new solutions allow – in conjunction with other actions taken like solar panels or re-use concepts for heat – saving of up to one-third of energy compared to the old plant. Amortisation is expected to be around two years.

In the latest use cases, the data from such energy efficiency modules is brought via OPC-UA and a Festo CPX-IoT Gateway to cloud or IoT platforms like Siemens MindSphere or Rockwell Factory Talk. Festo also provides its own cloud for deeper analytics of all its pneumatic and electric drive components and mechatronic sub-systems as a long-term target. Data is also fed into SAP HANA, Festo’s on-site option in the Scharnhausen factory.

The required apps are developed by Festo, and in the case of external cloud providers, are then installed in the MindSphere environment (using Siemens MindConnect LIB) or the Rockwell Device Analytics (via Shelby Appliance or Team ONE tools). The app for the Festo energy efficiency module inside these clouds or IoT environments allows easy visualisation, quicker set-up and parametrisation of the product and online visualisation during machine run-time. The data analytics support advanced diagnostic and condition monitoring concepts and could lead into predictive maintenance systems by combining data from different sources inside the cloud.

Today, a cloud based visualisation makes many things easier, but a high degree of expertise and IT knowledge is needed to make the devices communicate to clouds offered by the market today. In total, the Festo energy efficiency module reduces energy cost, and increases machine availability. Mindsphere, Factory Talk, Festo cloud, SAP HANA and many others allow easy visualisation and machine set-up, as well as global data analytics.

Festo Industry 4.0 products and solutions – At the SPS/IPC/Drives exhibition in Nuremberg in 2017, visitors could experience Festo’s new automation platforms with IP20 and IP65, IoT gateways and a direct link to a cloud. Eberhard Klotz, the head of the Industry 4.0 campaign at Festo, explains what contribution Industry 4.0 is already making to the booming automation technology sector today.

Festo Industry 4.0 products and solutions – At the SPS/IPC/Drives exhibition in Nuremberg in 2017, visitors could experience Festo’s new automation platforms with IP20 and IP65, IoT gateways and a direct link to a cloud. Eberhard Klotz, the head of the Industry 4.0 campaign at Festo, explains what contribution Industry 4.0 is already making to the booming automation technology sector today.

“Festo is already delivering some real automation technology products for the fourth industrial revolution including: integrated drive packages, modular valve terminals with OPC-UA and IoT gateways, decentralised Codesys controllers and autonomous mechatronic subsystems with IP20 or IP65. In addition, there are apps and cloud concepts ready for pilot projects. However, the top and most exciting innovation in pneumatics is the Festo Motion Terminal,” emphasises the expert in automation. The Festo Motion Terminal is the first automation platform to be designed as a cyberphysical system and replaces up to 50 individual pneumatic functions.

“Festo, in contrast to consultancies, has the advantage that it can draw on a wealth of user experience from pilot production projects in the Scharnhausen Technology Plant,” explains Klotz. This includes topics such as energy management and optimisation as well as innovative one-pieceflow concepts based on standardised networking, mobile maintenance with tablets or automated, flexible test systems for individual products. “This experience is also incorporated into our own products.”

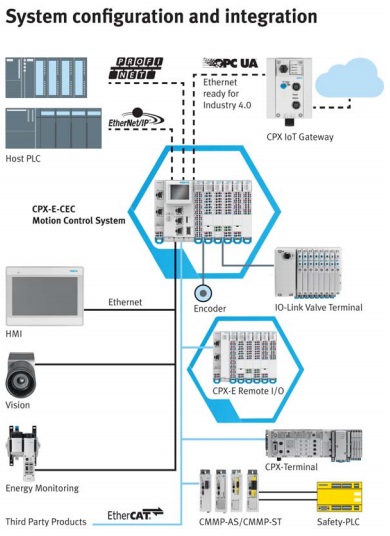

The Festo CPX-E Industry 4.0 automation system – The CPX-E system is a high-performance system for factory automation (IP20, the “E” refers to enclosures). This system consists of individual function modules that can be used to create a modular, compact and thus very flexible system. Depending on the module combination, the system can be used as a purely remote I/O system or as a – centralised or decentralised – control system for factory or process automation.

From a functional point of view, the CPX-E control units are designed as EtherCAT master controllers and motion controllers. These are highperformance control units which can be used both for extensive PLC functions and, in the Motion Control M1 variant, also for multi-axis applications with interpolation. The basis for this is the programming system CODESYS V3 with additional software libraries for both simple and complex motion control applications.

Festo can therefore offer a consistent portfolio for the decentralised automation of sub-systems and small machines/installations with IP20 and IP65, all in line with a flexible Industry 4.0 host environment.

Benefits for both, OEM and end-users – OEMs can improve their machine offers with the latest technology upgrades and cloud connectivity to be integrated into Industry 4.0 host environments. The Festo energy efficiency module allows advanced diagnostics and condition monitoring concepts for the pneumatic circuits of a machine as a whole or a modular segment of a machine. In addition, energy is saved by switching off unused machine modules/segments.

End users can improve their production by latest technology upgrades and cloud connectivity. Cloud analytics allow optimisation of business and production processes, higher OEE by predictive maintenance concepts and shorter downtime by better diagnostic support. The Festo E2M module saves energy by switching off unused machine modules or segments.

All customers benefit from the co-operation of market leaders: Festo in mechatronic motion control solutions and decentralised automation concepts, and the large PLC manufacturers and MES providers like Siemens, Rockwell, SAP and others.